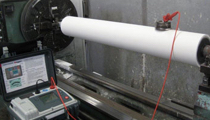

Rollers and coatings

WE CAN MANUFACTURE, RETREAD AND COAT FROM THE SMALLEST ROLLER TO THE LARGEST YOU CAN IMAGINE.

Maximum efficiency in roller coating.

We have the ability to produce the widest range of coatings for rollers, pulleys, wheels, tanks, pipes and all kinds of parts in any dimension for any industry that requires it.

Why trust KOALA®?

Find out why our coatings are the best option for your industry.

Specific formulations

We develop and integrate the ideal formula to excel in each application with compounds of the highest quality and the best selection of raw materials.

Wide variety of industries

We serve the needs of any sector, with thousands of custom-made compounds.

Strict quality control

We verify that each compound meets the requested dimensions and tolerances to operate at maximum efficiency.

Laboratory

We have the most complete laboratory in the sector, equipped with state-of-the-art machinery, having leading technologies and patents of our own, allowing us to validate our processes and products batch after batch.

Custom compounds with any elastomer

We have a wide variety of compounds for industrial use in all possible colors, hardnesses and characteristics. These are some of the elastomers available:

• Ceramic

• Ebonite

• EPDM

• Carboxylated rubber

• Hypalon

• Natural

• Neoprene

• Nitrile

• Nylon

• Polyurea

• Polyurethane

• SBR

• Silicone

• Teflon

• Thiokol

• Viton

Product engineering

Research, development and product engineering

We guarantee the optimal functioning of your coatings

At KOALA® we offer additional control, quality and production services to satisfy any type of special request in the roller field:

- Manufacture of metal cores.

- Complete manufacture of rollers.

- Repair of shafts and cores.

- Static and dynamic balancing.

- Non-destructive tests.

- Special compounds.

- Polishing.

- Special pieces.

- Sleeves.

- Electrostatic tests.

- Resistance and insulation tests.

- Machining of surfaces.

- Inspection and porosity tests.

- Linear, radial or angular grooves.

- Concave, convex, parabolic and conical crowning.

What type of coating do you need?

We manufacture custom-made and according to your needs.

Get in touch with us: